MAXIMIZING COMPRESSOR PERFORMANCE WITH PROVEN TECHNOLOGY

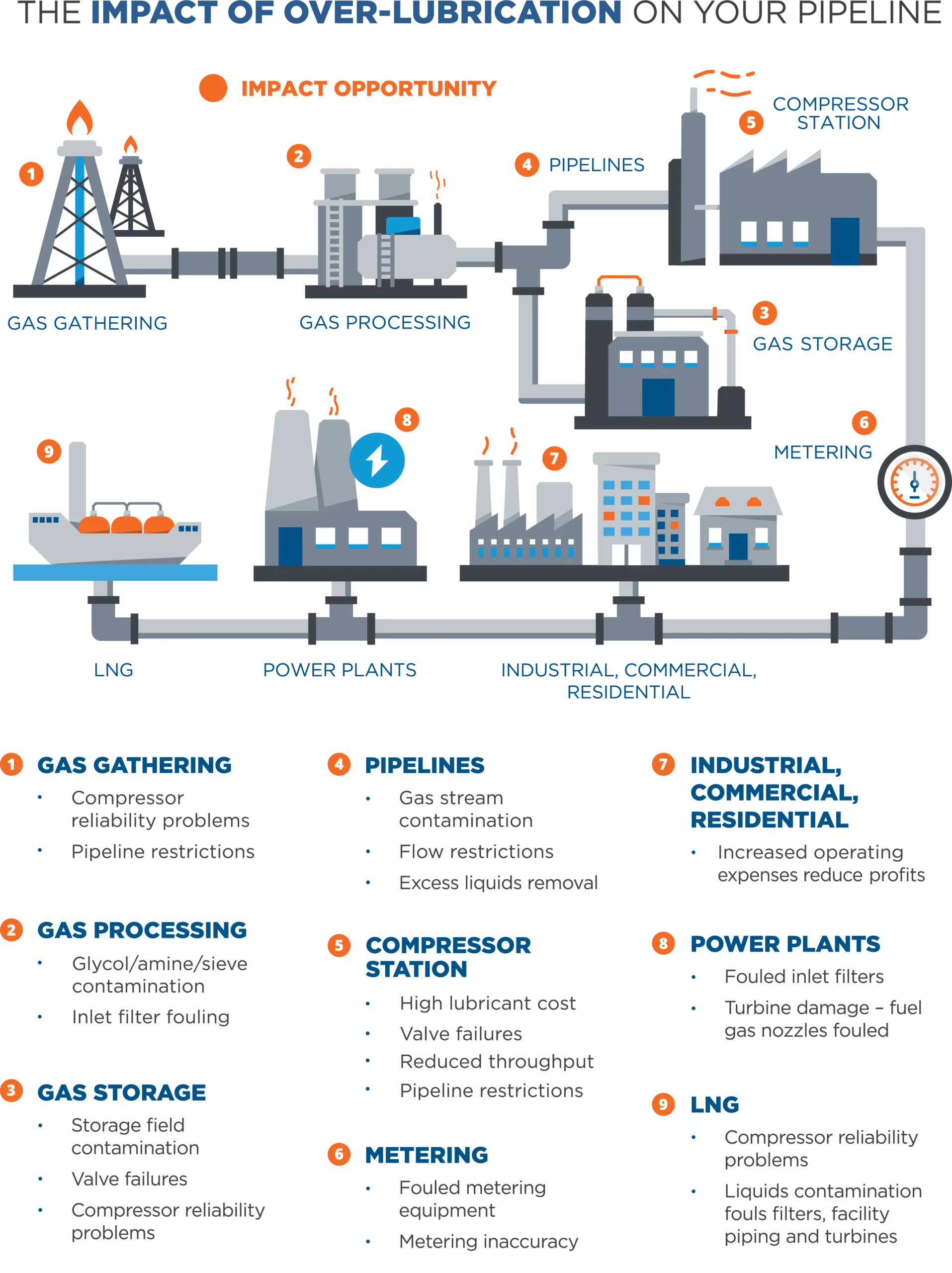

TriCip saves gas pipeline companies millions of dollars by eliminating lube oil carryover from compression that contributes to gas stream contamination.

By solving this pervasive problem, TriCip reduces valve failures, pipeline restrictions, fouled filters, pigging, processing contamination, metering inaccuracy, and damage to end-user equipment like power turbines.

Combining an advanced, proprietary lubricant and a state-of-the-art automated delivery system, TriCip delivers the precise amount of fluid necessary to ensure maximum compressor performance, improving uptime, enabling up to a 90% lubricant reduction for your gas compressors.

IMPROVE UPTIME AND ELIMINATE LUBE OIL CARRYOVER

Learn how a Sloan customer in gas gathering has benefited from implementing dozens of TriCip Systems on their new high-speed separable compressors.

TriCip Case Study: Protecting Your Critical Equipment and Bottom Line

The case study provides data analysis of gas quality improvements and operational/maintenance results from 3-1/2 years of a successful 90% reduction in compressor cylinder lubrication rates achieved by Sloan’s TriCip System. Learn more about how this customer saved millions of dollars.

TRICIP FEATURES & BENEFITS

Eliminates liquids contamination from compressor lube oil carryover for improved reliability and reduced downtime

Automatically adjusts lubrication rates for break-in and variable output applications to prevent over-lubrication, carbon buildup, catalyst fouling and excess emissions

BIB (Bag in Box) fluid delivery system guarantees contaminant free lubricant, providing increased reliability and uptime, extending the life of system components

Eliminates amine and dehy contamination, preserving the life of processing liquids saving time and money

Reduces pigging, fouled filters, metering inaccuracy, and the risk of damaging downstream equipment like turbines for increased profitability and reduced liability

Drastically reduces the amount of lubricant consumed to minimize expense and reduce the carbon footprint of your compression operation

What’s with the box?

Our BIB (Bag in Box) fluid delivery system is an end-to-end supply chain for your TriCip Fluid designed to eliminate contaminants. As lubrication rates decrease, it becomes increasingly important to eliminate contaminants from the lubricant supply. Day tanks, bulk storage tanks, and delivery via tanker truck are all sources of contamination. TriCip Fluid arrives via regular shipments in a specially designed box and achieves a level of fluid integrity not possible using other delivery systems. TriCip also eliminates the need for large bulk storage tanks and piping which enables significant cost savings and minimizes site liability due to the risk of spills.

Technical Specs

- Zones – 1 – 2 independent zones of lubrication

- Flow Rates – Up to 90% reduction from OEM rates

- Available for hazardous locations Class 1, Div. 2, Group ABCD

- Communications

- Serial or Ethernet available for all major PLC / SCADA platforms

- Outputs – Alarm relay, Max 250V, 6A (NO or NC)

- Power Requirements – 24V DC, AC single or 3 phase

- Tank Size – 2 x 20 liter removable BIB cartridges

- Filter Size – 10 micron

- High Pressure Relief Valve

- Up to 5000 PSI Pressure

- Corrosion Resistance – using stainless steel, nitride, anodized, or powder coated components