RELIABLE Lubrication Systems FOR CEMENT AND AGGREGATE PRODUCTION

PROVEN SOLUTIONS

Our advanced lubrication systems for Fuller Compressors used for pneumatic conveying and roller mills for precision grinding deliver performance our customers depend on to prevent costly shutdowns and equipment damage year after year.

Built TO BE BETTER

Sloan Lubrication products are designed, manufactured, and rigorously tested at our factory in Freeport, Pennsylvania to ensure dependable performance in the harshest environments, guaranteeing uptime and reducing operating expenses for cement and aggregates applications.

LUBRICATION Systems for CEMENT AND AGGREGATES

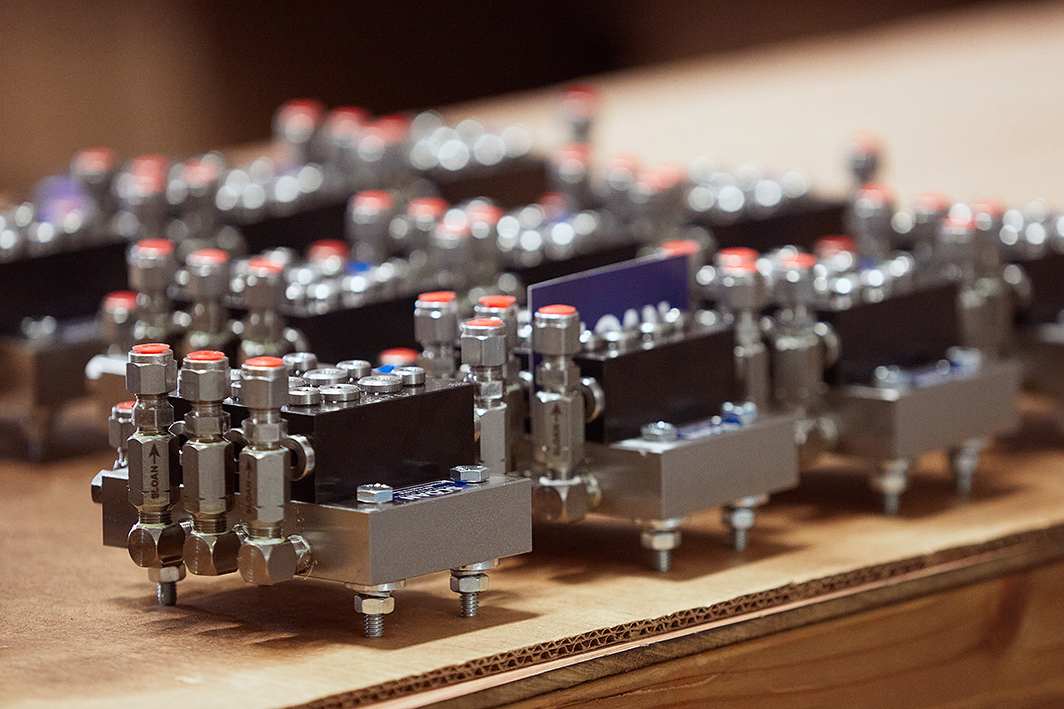

DIVIDER BLOCK LUBRICATION SYSTEMS

With series progressive divider blocks at the core, our systems accurately meter lubricant flow from a single pump to multiple delivery points to protect your equipment with reliable, fail-safe monitoring.

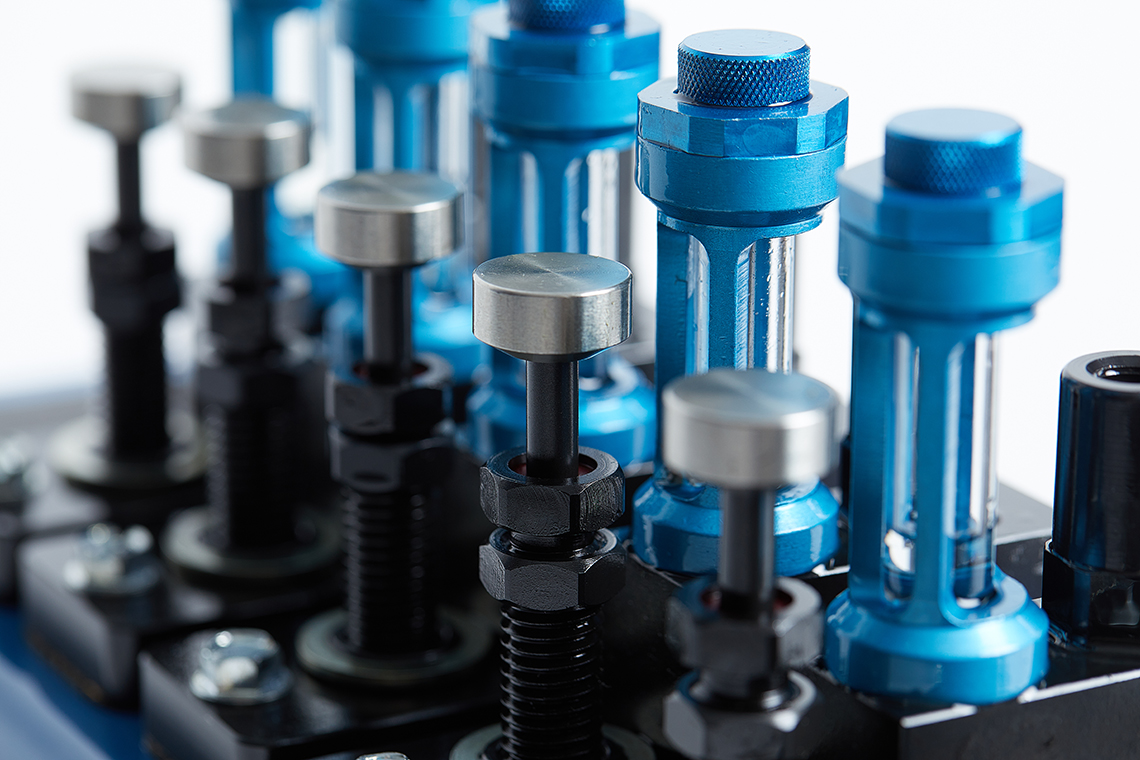

PUMP TO POINT LUBRICATION SYSTEMS

In applications where operators are responsible for system monitoring, our user-friendly systems provide dependable performance by utilizing a single SLS vacuum (box suction) pump to deliver lubricant to each delivery point with precision and reliability.

CUSTOM LUBRICATION SYSTEMS, ENGINEERED FOR YOUR SPECIFIC APPLICATION

From self-contained turn-key systems like our Watchman, to component kits that match the OEM footprint on legacy equipment, Sloan Lubrication Systems can custom build a series progressive divider block system or a pump to point system for nearly any machine.

We begin every project with a thorough evaluation of the application to gain an understanding of the unique operating conditions, challenges and causes for previous failures. Then we design a system that will exceed your expectations and provide dependable performance for the long haul.

BEFORE: Lubrication system on a Fuller Compressor in a cement plant

- Critical components caked in dust

- Unreadable indicators and gauges

- Lost productivity due to reliability issues

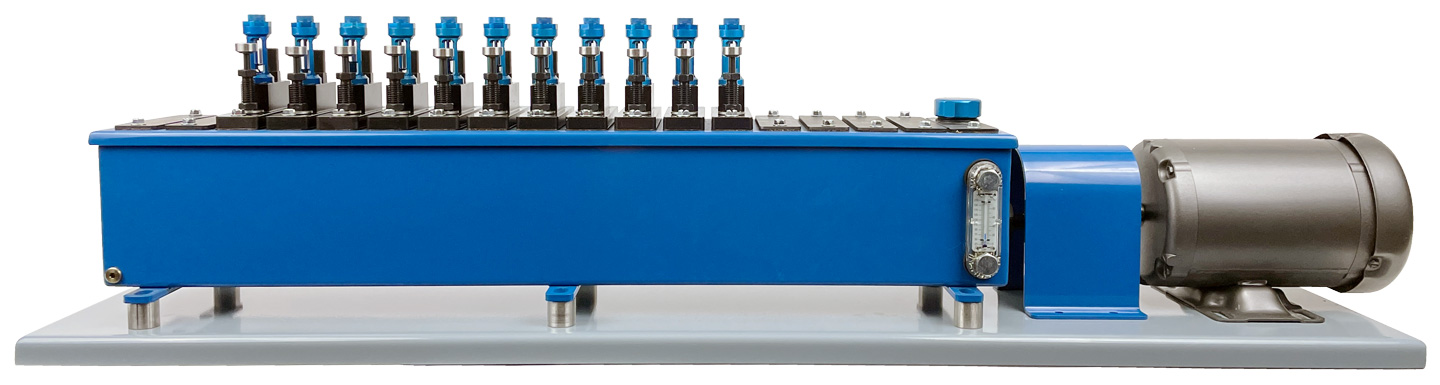

AFTER: Watchman Lubrication System in a sealed environmental enclosure

- Protected from dust, rain and cold

- Easy to operate and maintain

- Increased reliability and uptime

Trust

the

Experts

In properly designed lubrication systems, the leading cause of failure is lack of maintenance. Sloan Lubrication not only provides best-in-class system design and installation, but ensures long-term reliability and performance with comprehensive service, technical support, and operator training.

Emergency Service

On call 24/7

Field Service

Installation, service, maintenance

Technical Support

Our expert team is standing by

System Evaluation

Free consultation & failure analysis

Training

Keep your teams up to date

Engineering & Design

Custom solutions for challenging applications

Sloan Service Plans

Protect your investment with our service plans and extend your warranty coverage for up to five years.

Systems for CEMENT AND AGGREGATES

Robust, durable, and reliable, our Watchman is a tried and true plug and play system, precision engineered and tailored to your application.

Custom engineered lubrication systems designed specifically for your application and proudly backed by our century of expertise.

From custom designed system component kits to an array of replacement systems for legacy OEM compressors, we deliver with reliability.

Parts for CEMENT AND AGGREGATES

Manufactured to the highest quality standards for precise, fail-safe lubricant delivery.

You’ve got questions? We’ve got answers. Connect with our knowledgeable team today.

Toll Free – 800-722-0250 • International – +1-412-828-2420 • sales@sloanlubrication.com