RELIABLE Lubrication Systems and expert service for PLUNGER PUMPS

PROVEN SOLUTIONS

For more than 100 years, Sloan Lubrication Systems has been the industry’s trusted advisor for lubrication systems for plunger pumps.

Plunger pumps operate in extreme environments and need rugged and durable packing lubrication systems that can deliver against high pressures in the worst of conditions. Sloan Lubrication Systems manufactures custom electric driven pump to point systems, lubricator boxes, and pumps that meet the challenge.

Built to BE BETTER

Sloan Lubrication products are designed, manufactured, and rigorously tested at our factory in Freeport Pennsylvania to ensure dependable performance in the harshest environments, guaranteeing uptime and reducing operating expenses for plunger pump applications.

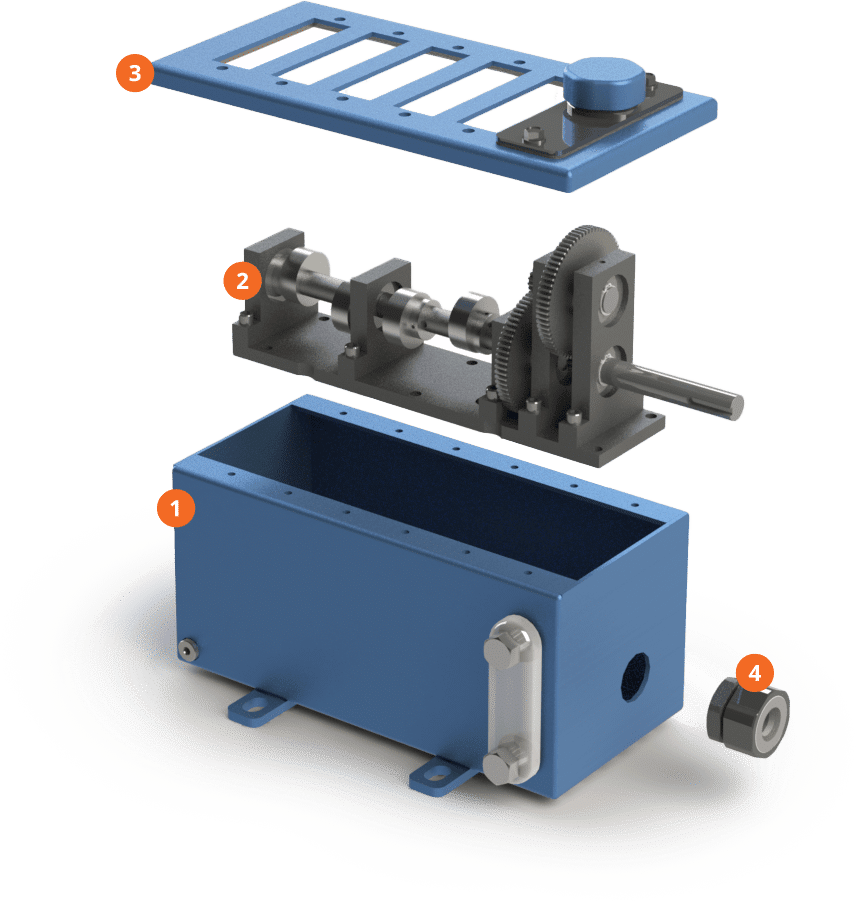

WHETHER YOU CALL THEM LUBE BOXES, LUBRICATOR BOXES OR BOX LUBRICATORS, WE MAKE THE BEST.

Features & Benefits

- 11ga cold-rolled, laser-cut steel construction with welded mounting feet

- Ball bearings throughout – no bronze sleeve bushings on shafts or gears

- Hardened CNC-machined cams and gears

- Powder-coated exterior and interior for improved corrosion resistance

- QPQ-nitrided exterior steel surfaces and overhung lip design for improved resistance to the elements

- Modular construction with CNC-machined baseplate and supporting structures

- 1/2” rise cams for longer adjustable pump range at any given rpm

Components

-

11 gauge cold rolled steel for torsional rigidity, and powder-coated inside and out for corrosion resistance

-

Drop-in drive assembly with a black nitride coating for long life, corrosion resistance, and simple maintenance

-

11 gauge laser cut steel lid with an overhung drop lip prevents contamination and is fully powder-coated

-

High permanence radial ball bearings, taper bearings and needle bearings for reduced wear and long life

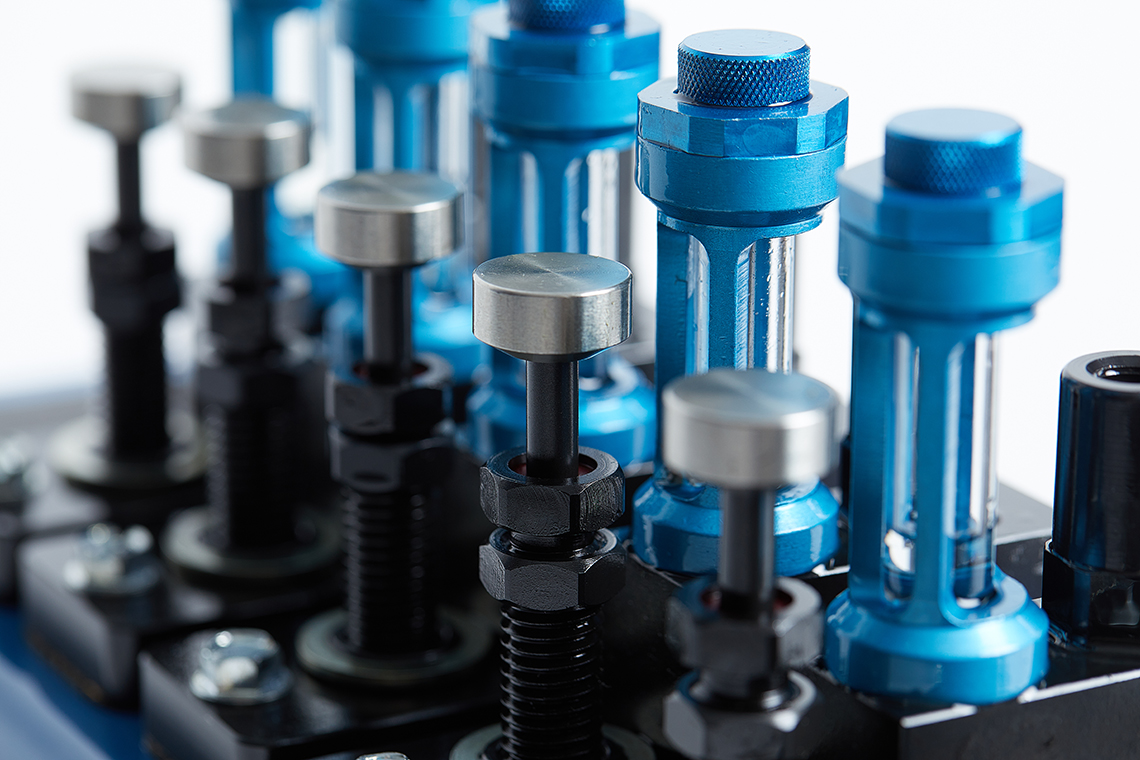

SLS PUMPS – RELIABLE, DURABLE, AND CORROSION RESISTANT

Description

Sloan Lubrication Systems’ high quality lubrication pumps are designed to deliver dependable performance for a wide range of applications. Our pumps are offered in three piston sizes to meet the volume requirements of any application.

Vacuum / box suction pumps feature an extra-wide sight glass for easy drop viewing for output adjustments as needed. Generally used for applications in which each pump serves one lubrication point and no delivery protection is required.

Features & Benefits

- Fits box lubricators SLS, CPI / Premier, Lincoln / McCord, Mega

- Standard mounting bolt centers (4.406”)

- Needle roller bearing for reduced friction

- High-performance piston seal ensures no leak by

- Corrosion-resistant plating, fully coated inside and out

- Hardened stainless steel piston for continued performance

- Extra-wide sight glass window for easy drop viewing

- Spring-loaded PTFE seal poppets on suction and discharge

- Self-priming pump with priming port for easy startup

Trust

the

Experts

In properly designed lubrication systems, the leading cause of failure is lack of maintenance. Sloan Lubrication not only provides best-in-class system design and installation, but ensures long-term reliability and performance with comprehensive service, technical support, and operator training.

Emergency Service

On call 24/7

Field Service

Installation, service, maintenance

Technical Support

Our expert team is standing by

System Evaluation

Free consultation & failure analysis

Training

Keep your teams up to date

Engineering & Design

Custom solutions for challenging applications

Sloan Service Plans

Protect your investment with a service plan and receive extended warranty coverage for up to five years.

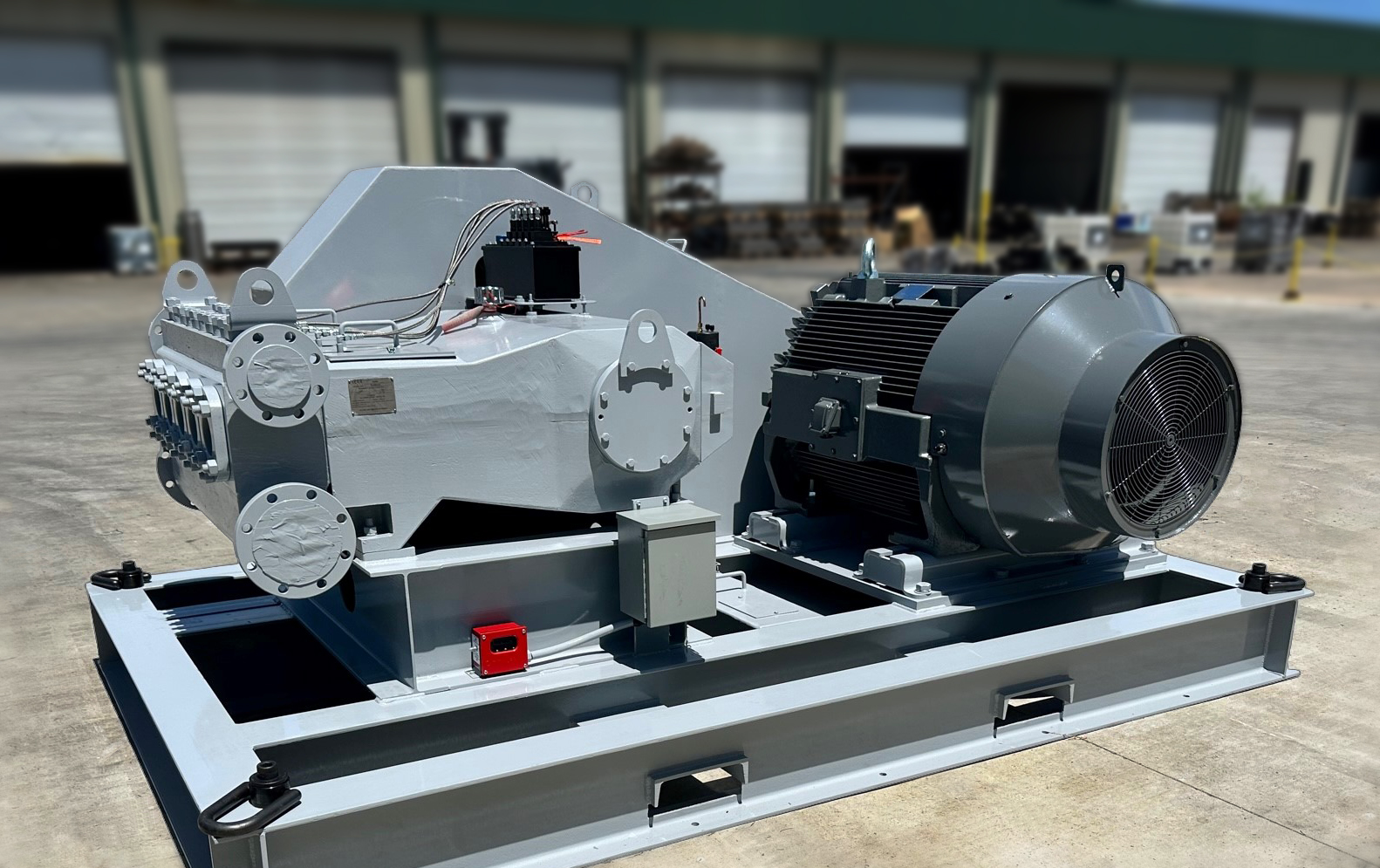

SYSTEMS AND Parts for PLUNGER PUMPS

Precision engineered for dependable performance in the most adverse conditions.

Custom engineered lubrication systems designed specifically for your application and proudly backed by our century of expertise.

From custom designed system component kits to an array of replacement systems for legacy OEM compressors, we deliver with reliability.

You’ve got questions? We’ve got answers. Connect with our knowledgeable team today.

Toll Free – 800-722-0250 • International – +1-412-828-2420 • sales@sloanlubrication.com