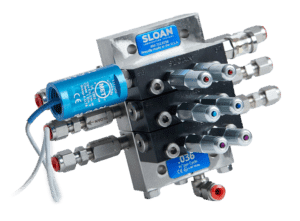

Description

Engineered to provide the best piston fit possible, our divider blocks effectively divide the total flow of lubricant delivered to all lubrication points. Designed specifically for low-flow, high pressure applications in compressors and engines, our divider blocks exceed the highest industry standards, ensure the optimal delivery of necessary lubrication to downstream points, and guarantee fail-safe shutdown.

Features & Benefits

- Integrated baseplate poppet checks ensure positive output

- Outlet ports machined to accept O-ring fittings and standard pipe thread fittings

- Integrated top and bottom baseplate sections reduce leak points

- Rear-mounting spacers prevent thermal expansion

- Corrosion-resistant nitriding withstands the most extreme environments

- All surfaces precision machined to prevent geometric deformations

- Tapered countersunk mounting bolts transfer force away from the bore, eliminating bore distortion

- Manufactured and tested to the highest industry standards

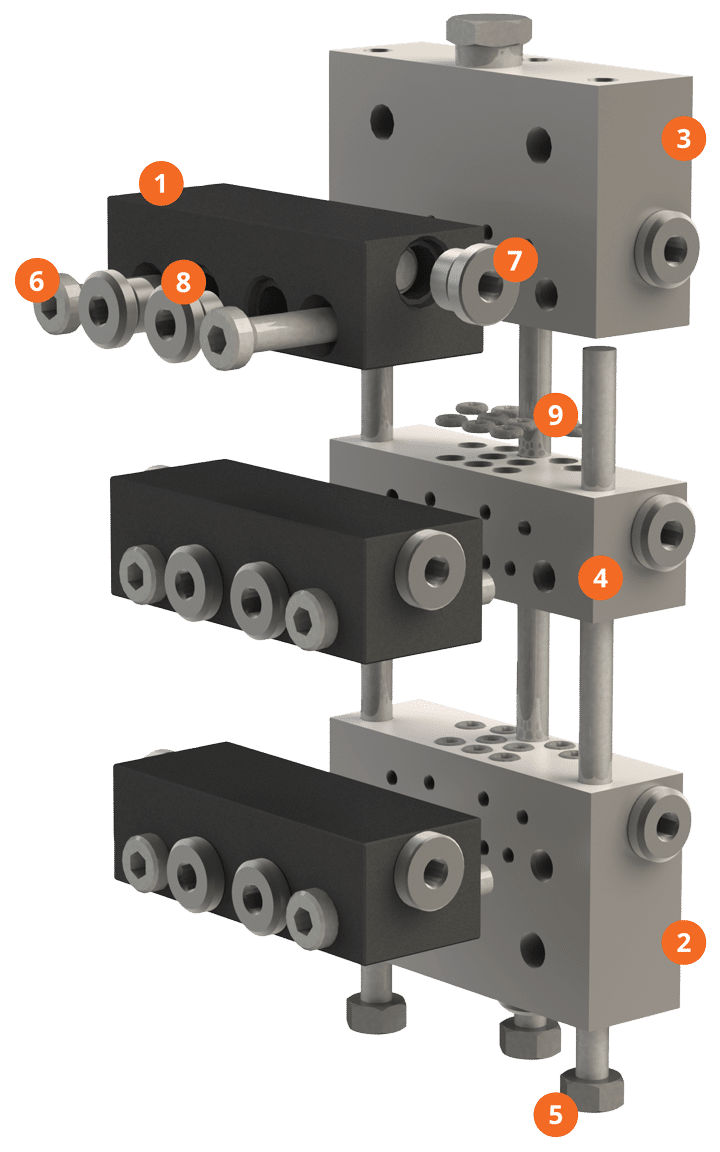

Assembly Components

Divider sections are available in 3T through 30T, and the displacement varies from .003in3 to .030in3

(.049cm3 – .492cm3).

- Divider Section – See Divider Section part numbers above

- SLS-D-Bottom – Baseplate bottom section w/inlet*

- SLS-D-Top – Baseplate top section w/inlet*

- SLS-D-Baseplate – Intermediate baseplate section

- SLS-D-T3 – Tie rod, 3 section (3-9 sections available)**

- SB-D-sectionBolt – Divider section bolt

- SB-D-SP – Divider section side plug

- SB-D-FP – Divider section face plug

- SB-O-V006 – Intermediate O-ring (Viton) ***

Not Pictured: SLS-D-Top-NI – Baseplate top section/ no inlet*

*Standard SLS/Trabon bolt centers – for Lincoln/Ariel add “L” after “D” in PN

** To specify length of tie rod, indicate section count (3-9) after “T” in PN

*** For Buna O-ring change “V” to “B” in PN