Many lubrication system problems are caused by contamination. Contaminants come in many forms, including water, air, and particulate. Sloan Lubrication Systems provides filtration solutions to make sure contaminate oil does not damage your equipment or create problems with your lubrication system.

Download our Filtration products data sheet HERE.

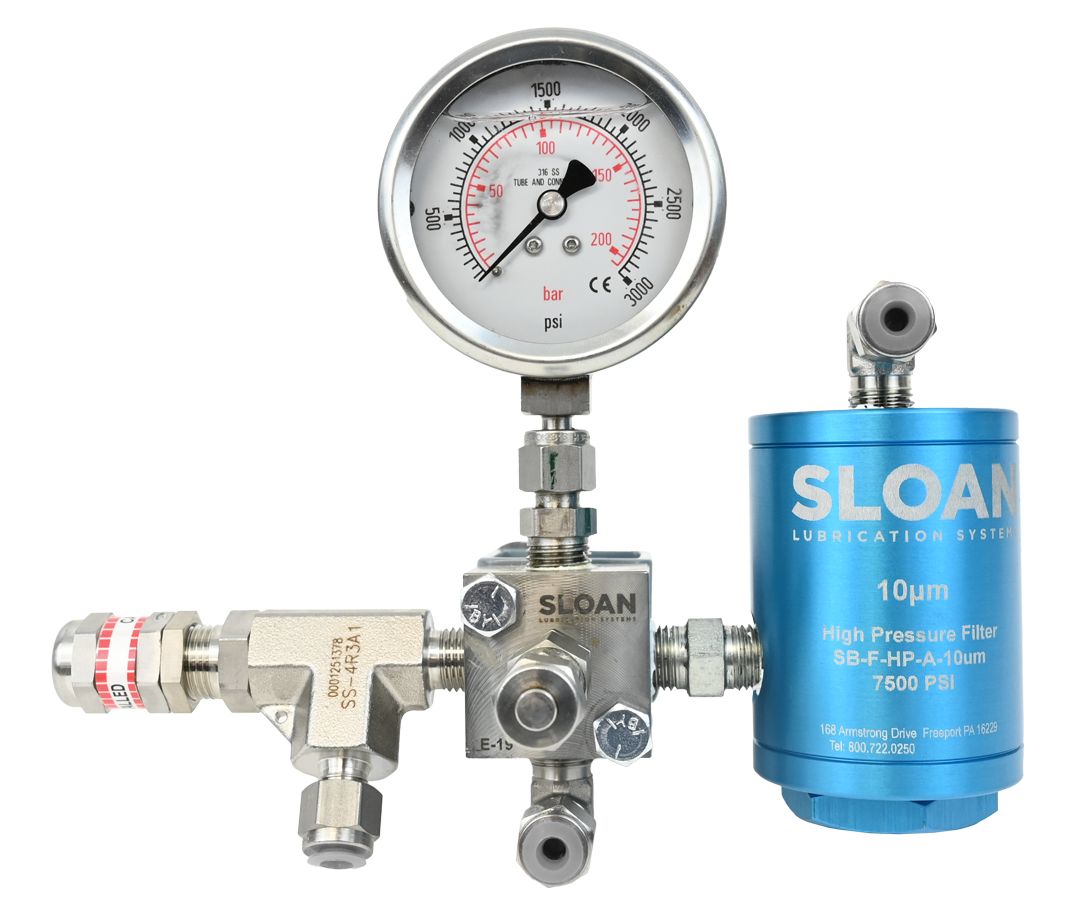

Gauge Assembly

Our gauge assembly provides multiple vital functions in a divider block system. It is the inlet for each lubrication zone and provides filtration, high pressure relief, visual pressure monitoring, and a purge point for maintenance and testing. The gauge assembly is available with a rupture relief valve that uses rupture disks, or a high pressure relief valve that resets itself once the pressure drops below its set pressure.

Features & Benefits

- 10, 25, 40, 90 and 150 micron filter elements available

- Available with a rupture disk relief assembly or a high-pressure relief valve to any set pressure required

- Sintered bronze element protects divider block’s extremely tight tolerance pistons

- Filter element allows easy replacement without disturbing tubing

- Vertical installation of element parts protect gaskets upon installation

- Purge point with a terminal check valve used for high-volume purging of the divider block and lubrication lines

Download our filtration components data sheet for product details.

Air/Water Traps

One of the most concerning contaminants in divider block lubrication systems is water, which can cause corrosion and the loss of lubricity in oil. Water can enter lubrication systems from a contaminated supply, or form as condensation inside tanks. Air can build up in pumps and create an airlock, which prevents oil flow. Our air/water traps are designed to provide a reliable solution to both problems and keep systems functioning properly.

Features & Benefits

- 1/8 inch female NPT bleed port top with installed valve

- Pyrex Tube – handles all oil types

- Anodized aluminum for superior corrosion resistance

- Viton O-rings

- 1/4 inch female NPT inlet and outlet

- Pressure relief

Details

Max Oil Pressure 125 psi

HP Filters / Element

Our high pressure filters provide your divider blocks with an improved level of protection from particulate contamination. Our filters use a sintered bronze element available in several different sizes to provide the protection your divider blocks need. In addition, we offer our sintered bronze filter elements which come as a kit with two new springs and gaskets available in several different levels of filtration.

Features & Benefits

- Filters available in anodized aluminum or stainless steel

- Filter element comes in 10, 25, 40, 90 and 150 micron

Spin-On Filters

Our custom lubrication systems can be designed to utilize an existing header supply. In this case, it is important to knock contaminants down to a level that won’t damage your lubrication system, which has components that are typically of a higher tolerance than the rest of the process. Our spin-on filters provide the high volume, bulk filtration that your system needs to operate reliably.

Desiccant Breathers

Gravity feed lubrication systems need to have a vented supply. Humid environments and temperature changes can cause water to collect in vented supply tanks. Our desiccant breathers provide a solution to that problem. When installed on a supply tank, the desiccant removes moisture from the air as it enters the tank, preventing water from contaminating your lubrication system.

Y-Strainers

Contamination frequently finds its way into tanks while they are being filled. Our Y-strainers remove large particles from your oil supply before it reaches the pumps, preventing them from being distributed throughout the system.