Wizard Monitor

Providing constant monitoring for reliable protection of your critical lubricated equipment.

Features & Benefits

- Tracks and displays total oil delivery for up to four zones

- Simple programming and setup with 31/2” color LCD touchscreen

- Compatible with all PLC systems via MODBUS interface

- Continuous log file recording via internal and USB export

- Signals a failure to an alarm upon flow rate drop

- Provides for automatic shutdown if flow rate drops

Details

Power supply

90-264 VAC, 47-63 Hz / 12-48 VDC 15 W max

Inputs

4 Zone proximity switches (low voltage dry contact)

1 Total display switch

1 Arm/disarm circuit

Outputs

4 Zone alarm relays 250 V max 5A (NO) / 3A (NC)

1 Power fail relay 250 V max 5A (NO) / 3A (NC)

Communication

1 RS485 Modbus RTU

1 10 / 100 Ethernet (Web server + MODBUS TCP / IP)

Storage Onboard

512Mb; minimum 2 years logging 1 entry per minute

External USB – CSV file format

Magnetic Proximity Switch

Simple yet effective patented spring-free operation.

Features & Benefits

- Anodized aluminum body and stainless steel wetted parts

- Spring-free design eliminates wear parts

- Fully enclosed design eliminates leak paths

- Removable magnetically captive pin for easy cleaning and operation verification

- Fully enclosed reed switch and PVC jacketed cable

- Easily separable magnet housing

- Normally closed switch design for simplified troubleshooting and circuit verification

- Precision-manufactured reed switch designed for millions of closures at low voltage

- Follows piston travel and reports each block cycle to the Wizard Monitor

- US Patent 8575921

Details

Switching voltage (DC or peak AC) 200V

Switching current (DC or peak AC) 0.5A

Carry current (DC or peak AC) 1.25A

Static resistance (@ 0.5, 10mA) 200

Insulation resistance (@ 100V) 1010

Sensor resistance (@ 40% overdrive) 480 mOhm

Magnetic Cycle Indicator

Provides instant verification that pistons are operating effectively.

Features & Benefits

- Stainless steel construction

- Gold ring magnet indicates piston cycle

- Instant visual verification of each divider block cycle

- Spring-free design eliminates wear parts

- Fully enclosed design eliminates leak paths

- Removable magnetically captive pin provides easy cleaning and operation verification

- Confirms Magnetic Proximity Switch operation

- Verifies flow rates displayed on system monitors

- US Patent 8575921

Gauge Assembly

Precision machined stainless steel manifold and fittings aluminum filter housing, and high-pressure relief assembly provide high-performance, durability, and accuracy. Available with a rupture disk assembly or a high-pressure relief valve.

Features & Benefits

- 10-micron high pressure filter element with optional 25, 40, 90 and 150 also available

- Available with a rupture disk relief assembly or a high-pressure relief valve to any set pressure required

- Sintered bronze element protects divider block’s extremely tight tolerance pistons

- Filter element allows easy replacement without disturbing tubing

- Vertical installation of element parts protect gaskets upon installation

- Purge point with a terminal check valve used for high-volume purging of the divider block and lubrication lines

Resettable Fault Indicator

Features & Benefits

- Spring-actuated

- Resettable and reusable

- No discs to replace

Air / Water Trap

Removes water and air for oil supplies upstream of pumps.

Features & Benefits

- 1/8 inch female NPT bleed port top with installed valve

- Pyrex Tube – handles all oil types

- Anodized aluminum for superior corrosion resistance

- Viton O-rings

- 1/4 inch female NPT inlet and outlet

- Pressure relief

Details

Max Oil Pressure 125 psi

Purge Pump

Features & Benefits

- Easy-to-see oil level

- Machined aluminum reservoir

- Flexible 36” hose with short bend radius for convenient use in used in hard-to- reach areas

- Integral check valve

- 3,000 psi oil-filled pressure gauge

- Includes both Parker and Swagelok 1/4” OD fittings

- Other fitting brands available upon request

Details

Rated Pressure 3,000 psi (5,000 psi option available)

Chamber Material Anodized aluminum/glass Compatible with all oil types

Chamber Capacity 1 pint (0.4L)

Check Valves

Positive protection for greater system reliability.

Single Poppet Check Valve

Features & Benefits

- Soft-seat poppet design

- Stainless steel

- Available in outlet and terminal configurations

- 400º F maximum temperature

- 1/8” MPT x 1/8” FPT check

Details

Inlet 1/8” FPT

Outlet 1/8” male NPT or 1/8” NPT

Material 303 stainless steel

Working Pressure 8,000 psi

Omni-Check Valve

Features & Benefits

- Omni-check soft-seat double-poppet check valve for increased reliability or choose hard-seat with stainless steel balls

- Provides positive sealing under all conditions

- 400º F maximum temperature or available with Buna seals for ammonia service with maximum temperature rating of 250º F

- Available with any fitting combination

Details

Inlet 1/4” FPT

Outlet 1/4” NPSF

Material 303 stainless steel

Working Pressure 8,000 psi

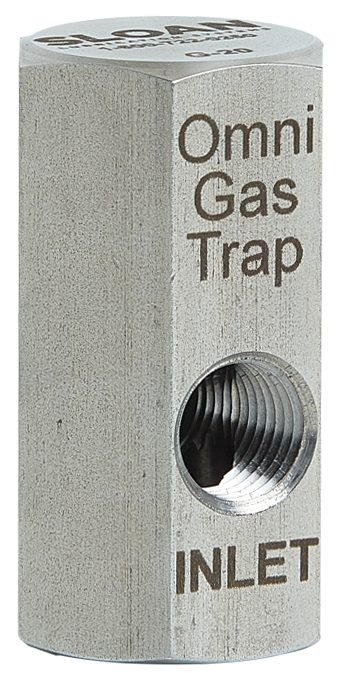

Omni Gas Traps

Prevents gas from migrating back and interfering with the operation of divider block lubrication systems.

Features & Benefits

- Eliminates the possibility of gas passing back into your lube lines, guaranteeing there is always a pool of oil on the “outside” of a check valve

- Gas cushion reduces pulsation up the lubrication lines for longer check valve life

- Remedies outlet check valve failure problems and gas blowback issues

- Helps to optimize check valve performance

- Provides added protection of oil delivery

Details

Inlet 1/4” female NPT

Outlet 1/4” male NPT or 1/8” male NPT

Material Stainless steel

Working Pressure 8,000 psi