What does it mean at Sloan Lubrication Systems when we talk about being a “frictionless” business partner? For us, it is about the way we meet our customers’ needs. When a customer calls looking for anything from a small part to a large system, they are immediately connected to our knowledgeable staff who can assess their needs and provide solutions-driven expertise. Our goal is to make the entire process smooth from start to finish.

As we continue to invest and innovate, some changes we are implementing include a state-of-the-art Customer Relationship Management system, an upgraded ERP system that enables us to rapidly ship the most critical components, a reorganization of our Field Service department, and the expansion of our sales team – all to better serve our customers.

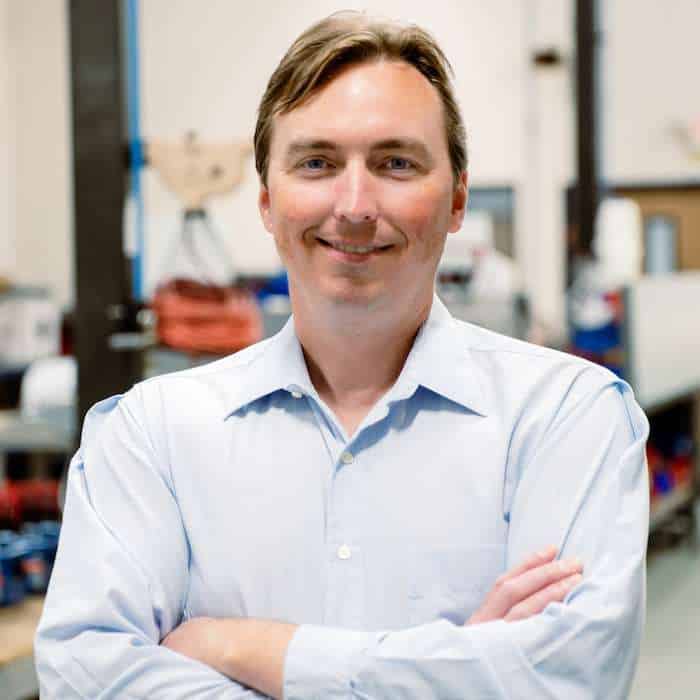

To further Sloan Lubrication Systems’ commitment, we have created a new role to maintain our focus on the frictionless customer experience. Eric Sloan, the middle son of the fourth generation Sloan family, will serve as the Director of Marketing and Business Development. In this role, Eric will work to expand our account management process with the goal of continuing to make our customer service even smoother.

As the manager of marketing communications for the past several years, Eric has been telling the story of Sloan’s four generations of success and helping to make it easy for customers to connect with the products and services that are the best fit for them. In his new role, Eric will build on these efforts in a way that has more of a direct impact on customers and will focus on continuing to enhance Sloan’s frictionless customer experience.

At Sloan Lubrication Systems, our commitment is to provide our customers with the best, which is why we focus on constant improvement. While our products and services are known to be the highest quality on the market, we don’t rest on our laurels.

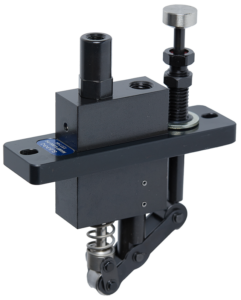

The reliability of our lubrication systems is directly linked to the fact that Sloan is the only lubrication system company that manufactures all the key components of its systems. This enables constant feedback from the field that allows us to fine tune even the most minor components for maximum performance. Our services are the perfect complement to our products. Our team is highly skilled with deep industry expertise and is dedicated to providing the best customer service in the industry.

It is not always easy to maintain the level of quality products and services that our customers have come to expect from us, but we know that providing a stellar customer experience is the clearest and best path to gaining trust and forming long-term partnerships.

Superior products and outstanding service have been the guiding business principles for Sloan Lubrication Systems for more than 100 years.

Meet Eric:

Eric joined Sloan Lubrication Systems in 2008 as a honing machine operator and has held positions in assembly, operations, and sales. He served as marketing communications manager from 2020 – 2023 and in 2024 started in the newly created role of director of marketing and business development. Eric earned his undergraduate degree from the University of Oregon and his MBA from the University of Portland.

What excites you the most about this role?

I am excited about having a more direct impact on providing a positive customer experience. I learned how important it is to provide excellent customer experience from my dad Walter Sloan, and I look forward to finding new ways to keep that goal front and center as we continue to grow.

What sort of challenges are you expecting?

I have seen many examples of companies losing sight of customer needs as they grow, and it is my mission to make sure that does not happen at Sloan. Sure, growth requires process, but there is no reason that frictionless customer service cannot be built into the process; in fact, it should enhance it. There are plenty of places our customers could go to buy cheap parts at commodity prices. They come to us for quality – a quality experience and quality service. And I plan to make sure we do not disappoint.

Did You Know?

Lubricator pumps are prone to airlocking. If you suspect an airlock because your pumps are moving but not pumping, SLS pumps are designed with a bleed port to help solve this common issue. Simply loosen the set screw on the front of the pump and let oil flow until you do not see any more air bubbles. Tighten the screw again and you should be good to go. Talk to one of our team experts or learn more here.