For decades, Sloan Lubrication Systems has been helping customers prevent the harmful effects of power and compressor cylinder over-lubrication, reducing lube-oil carryover on compressor cylinders, carbon build-up and excessive wear on power cylinders, and providing longer valve life.

Through our products and services, our customers have eliminated additional expenses from downstream effects of carryover such as fouled filters, pipeline restrictions, increased pigging requirements, metering station contamination, and the risk of turbine damage. But when asked if they can quantify the overall savings for us, they often scratch their heads because so many of the expenses of excess lubricant are hidden. The expense is often unaccounted for and is absorbed in typical operations like pigging, or they impact a different side of the business and the connection to over-lubrication is never made, making it nearly impossible to quantify the impact gas stream contamination can cause.

Until now.

Join us on Monday, October 3, at the Gas Machinery Conference, when CJ Sloan of Sloan Lubrication Systems and Keith Schafer of Black Rock Resources will present, The High Cost of Over-Lubrication – Quantifying the Negative Impacts of Excessive Power and Compressor Cylinder Lubrication on Natural Gas Pipeline Operations. This unique presentation provides a detailed account of our journey to create a working model to quantify the negative impacts and help the industry understand the real cost of over-lubrication.

CJ Sloan

Keith Schafer

This will be the third year that CJ and Keith have presented on the topic, beginning with a presentation of the work Sloan did installing 144 TriCip Systems for TC Energy, which resulted in reducing overall compressor lubricant consumption by 88%. We reported on the benefits of this project after a year, and this presentation is the “capstone” of the series designed to get to real numbers that pipeline operators may face in terms of expenses.

This presentation is in conjunction with Sloan Lubrication Systems 100 year celebration. What started as a dream shared by three brothers, is now a dream come to fruition as the 4th generation (and again 3 brothers) are laying the groundwork for another century of service. Please join us at the Fort Worth Omni Hotel ballroom at 5:30 pm on Sunday, October 2, for great food, drinks and the celebration of a century.

Brian, Eric, and CJ Sloan

Once again, we want to thank you, our dear friends and customers, for the opportunity to serve you for 100 years running.

Did You Know?

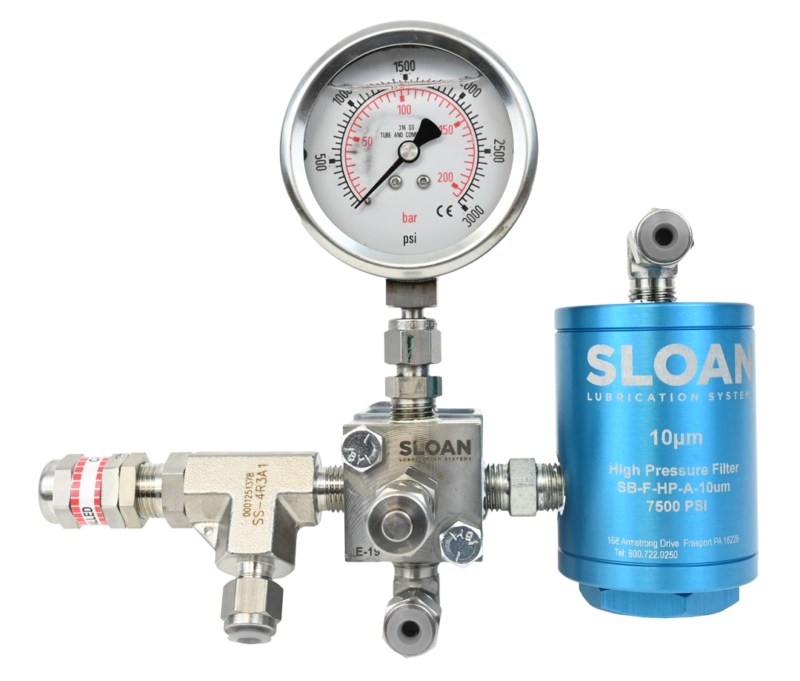

In certain applications, rupture relief valves can be replaced with high pressure relief valves that automatically reset. Get in touch with us to see if this will work for your application.