Description

SLS lubricator boxes feature cold-rolled, laser-cut steel construction with powder-coated interiors and exteriors for improved corrosion resistance and superior reliability.

Features & Benefits

- 11ga cold-rolled, laser-cut steel construction with welded mounting feet

- Ball bearings throughout – no bronze sleeve bushings on shafts or gears

- Hardened CNC-machined cams and gears

- Powder-coated exterior and interior for improved corrosion resistance

- QPQ-nitrided exterior steel surfaces and overhung lip design for improved resistance to the elements

- Modular construction with CNC-machined baseplate and supporting structures

- 1/2” rise cams for longer adjustable pump range at any given rpm

Components

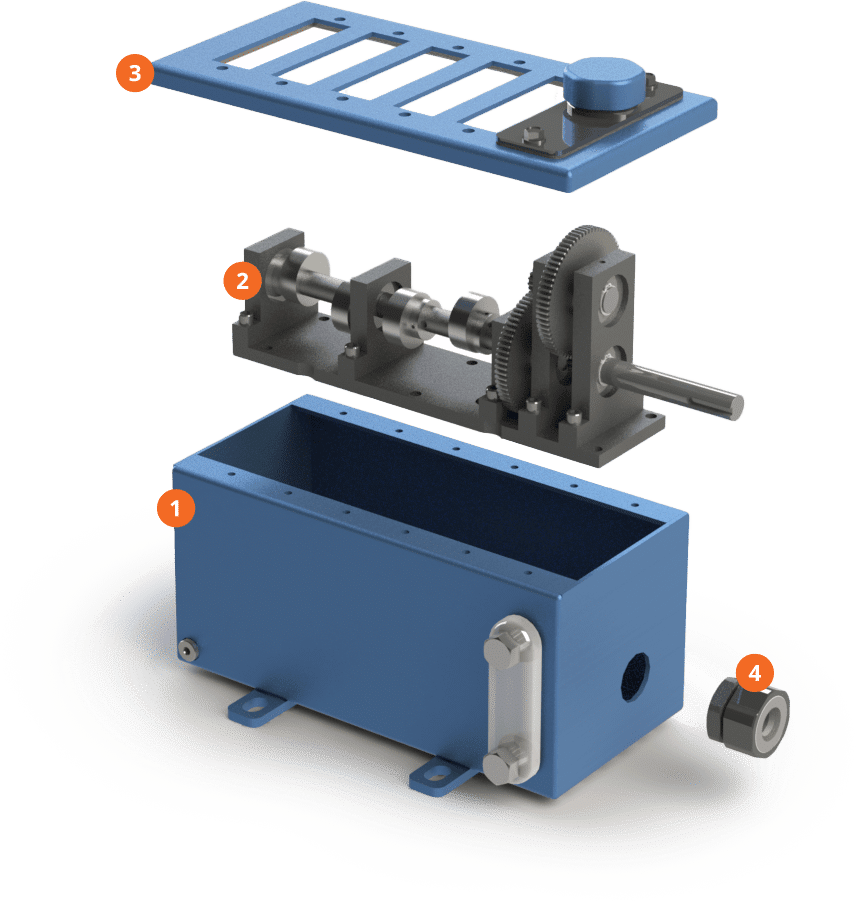

-

11 gauge cold rolled steel for torsional rigidity, and powder-coated inside and out for corrosion resistance

-

Drop-in drive assembly with a black nitride coating for long life, corrosion resistance, and simple maintenance

-

11 gauge laser cut steel lid with an overhung drop lip prevents contamination and is fully powder-coated

-

High permanence radial ball bearings, taper bearings and needle bearings for reduced wear and long life

Operating Conditions

Maximum working pressure

10,000 psi

Maximum input speed

1,800 rpm (90:1 ratio models)

Maximum cam shaft speed

60 rpm

If your compressors and equipment have more specialized needs, we’re here to help you learn more about our custom lubricator boxes.

We have custom and off-the-shelf lubricator boxes to meet your every need.

Size – from 2 – 32 Pint Capacity

For all makes and models of compressor:

- Cooper

- Clark

- Worthington

- Ingersoll Rand

- GE

- Gemini

- Superior

- Dresser Rand

- Ariel

- Penn

- Union

- CIP

- Joy

- Ajax

- CFA

- And many more

We manufacture lubricator boxes for applications including plunger pumps, food processing equipment, refrigeration, water treatment, and saw mills.

If your application requires a lubricator box, Sloan Lubrication Systems likely has what you need. Contact our sales team to find out more.