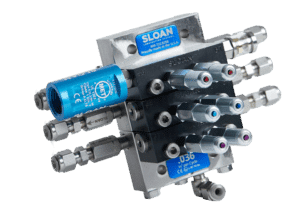

A divider block is a divider block, right? Except when it isn’t. Divider blocks are the core wear component of lubrication systems. They accurately divide the lubricant flow and meter it out to all delivery points, as well as act as the primary fail-safe, protecting your equipment from lubrication failure.

But not all divider blocks are created equal. Some are simply not up to the task of critical machinery lubrication, especially where high pressures are involved. Poor piston fits, manufacturing defects, cheap materials, and machining short-cuts are some of the reasons why all divider blocks are not the same. When any one of these factors is present, divider blocks cannot be relied on to accurately meter lubricant flow or deliver fail-safe operation. These common problems cause unreliable lubricant delivery leading to equipment damage, expensive repairs, and downtime.

While all available divider blocks share certain characteristics, there is only one manufacturer that consistently delivers divider blocks of the quality necessary for dependable critical machinery lubrication backed by over 100 years of experience, and that is Sloan Lubrication Systems.

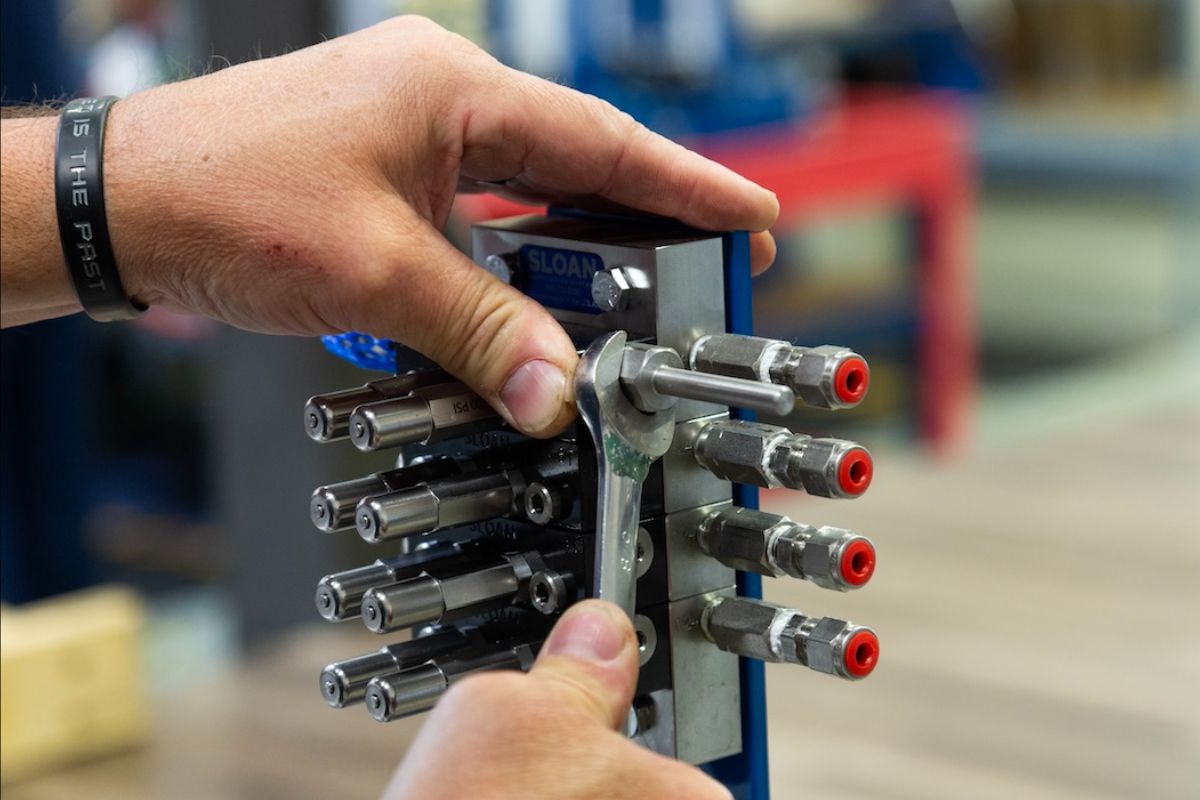

Sloan is the only full-service lubrication system provider that manufactures its own divider blocks. Through the years, we’ve tried all the mass-produced divider blocks on the market, and they all let us down. So we set out to make a better divider block and, for the past 15 years, we have been precision machining our line of divider blocks in-house. Our extensive experience with divider block lubrication systems taught us what worked and what didn’t, and we applied that knowledge when we reengineered the divider block. Today, our Sloan Lubrication System (SLS) Divider Blocks set the standard by which all divider blocks are judged.

We started with a few givens.

-

Our divider blocks had to be backwards compatible with other existing manufacturers’ divider block footprints as well as our own.

-

They had to operate reliably in high-pressure applications.

-

They had to be accurate, robust, and have a long lifespan.

We utilize state-of-the-art precision machining to manufacture our blocks to the tightest possible tolerances. Salt-bath nitriding provides exceptional corrosion resistance and durability. All stainless-steel hardware and baseplates guarantee a long-service life, and all of Sloan Lubrication Systems’ divider blocks are 100% tested before they leave the building.

Our divider blocks are the best because we sweat the details. In fact, since we reengineered the divider block and invested time and resources to enable us to manufacture them ourselves at our factory in Freeport PA, there hasn’t been a single case where a Sloan block had a manufacturing defect that caused damage to a customer’s equipment This level of dependability, reliability and quality is something that Sloan Lubrication Systems is very proud of being able to deliver to our customers. To find out more about what sets Sloan’s divider blocks apart, check out our Divider Block page on our website and download our product sheet.

Did You Know?

Sloan Lubrication Systems provides technical training. Whether you need a custom class for one person or 100, onsite, remote, or virtual, we have all your divider block training needs covered. Check our training page or contact us by email or phone to find out more and schedule a session today.