Well folks, the 2022 Gas Machinery Conference was certainly one to remember. Thanks so much to all of you who stopped by our booth to say hello. For those who were able to attend our Century Soiree, we hope you had a great time. We know we sure did and we appreciate your continued support of Sloan Lubrication Systems.

This year’s show was fantastic, with good food, great attendance, and fun events. Thanks so much to the team at the GMRC for making it all happen. If you weren’t able to attend this year’s event, we highly recommend putting it on your schedule for next year. One of the most valuable parts of the conference (besides visiting with great friends, old and new) is having the opportunity to attend presentations by industry leaders on the important topics that will impact the natural gas industry for years to come.

Particularly interesting at this year’s conference was the industry’s focus on finding new ways to do what we do best – keep homes lit and warm and keep critical industries operating, while continuing to focus on reducing our environmental impact.

One of the major discussion topics this year was hydrogen. Presentations covered experiments on hydrogen blending, types of machinery used for hydrogen transport, and the potential impact caused by the presence of hydrogen in gas streams on existing equipment like compressors and pipelines. It is great to see how much energy our peers are dedicating to reducing greenhouse gas emissions. If this year’s show was any indication, hydrogen is going to be a big part of the strategy going forward and we’re looking forward to helping customers mitigate any potential risks with blended hydrogen gas streams by applying proper lubrication.

It’s important to keep in mind that, while experiments on hydrogen blending make headlines and attract huge investments, the benefits may take several years to evolve. There are significant ways to make positive impacts today that should not be ignored. If you joined us for the presentation made by CJ Sloan of Sloan Lubrication Systems and Keith Schafer of Black Rock Resources, you know what we are talking about – lubrication.

Pipeline throughput, engine and compressor efficiency, and valve life are all negatively impacted by excessive lubricant. Over-lubrication creates carbon build-up in power cylinders, and fouls catalyst and exhaust equipment in engines. It carries over from compression, fouling filters and metering stations, causing pipeline restrictions, reducing reliability and increasing downtime.

All of these problems are often accepted as the cost of doing business in our industry, but they do not have to be. At Sloan Lubrication Systems, we’ve made it our mission to change the status quo. By addressing deficiencies in your existing lubrication systems, or by installing one of our Watchman Lubrication Systems, we can likely reduce your lubrication rates by up to 50%. Our revolutionary TriCip Solution can reduce your lubricant consumption by as much as 90%.

We have solutions right now that can have a dramatic and immediate impact on your business and your carbon footprint. To find out more about our systems and service, or to get a copy of CJ and Keith’s presentation, contact us today. We are always here to help.

Did You Know?

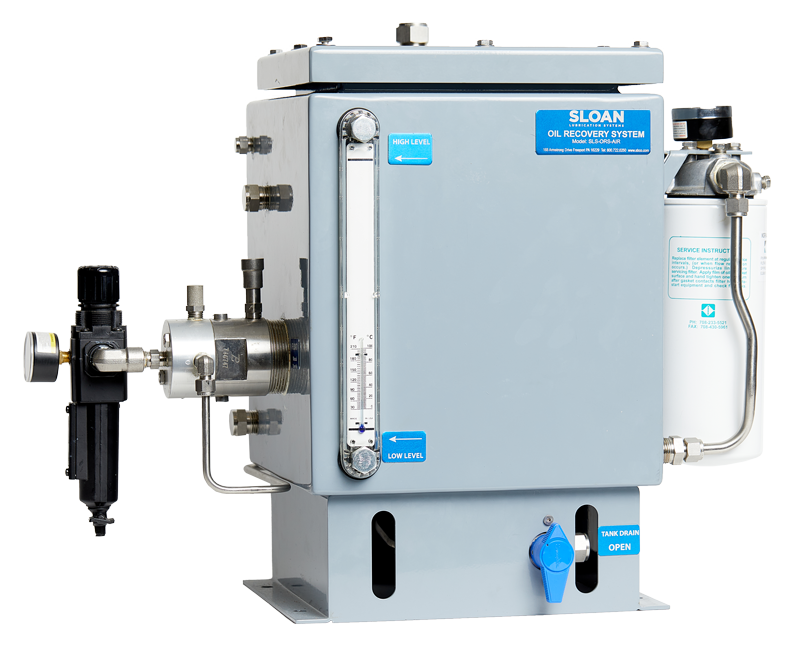

Did you know we have a solution for collecting and reusing crank case oil that gets past the wipers and into the compressor distance piece?

Our Oil Recovery System is an easy to implement, off-the-shelf solution to help you start saving today. Don’t waste money – recover it.