At Sloan Lubrication Systems, our team is committed to providing a smooth customer experience. Our highest aspiration is to be a frictionless business partner, offering expert lubrication services and seamless care from start to finish. This elevates our service offerings through our commitment to go beyond the expected. Our service team takes pride in their work, responds quickly to customer needs, and holds themselves to the highest standards from the moment they arrive on site to the completion of every job.

When it comes to lubrication system installations, preventative maintenance, emergency service, and lube rate optimization, there is no team more experienced than Sloan’s. While we often sing their praises for the work they do, it is ultimately the positive comments we receive from customers that mean the most. Customers speak of our team as being hardworking and disciplined, committed to quality, friendly, and dedicated to jobs done right. That is frictionless service at its best.

Consistently receiving this type of customer feedback is a testament to our team and the experience they bring to the job. But seeing them in action is even more impressive, and we recently had the chance to do just that. Along with Steve Spotts, our VP of Sales, we visited a worksite where our service team was completing a multi-unit TriCip installation at a new compressor station for a major natural gas midstream customer.

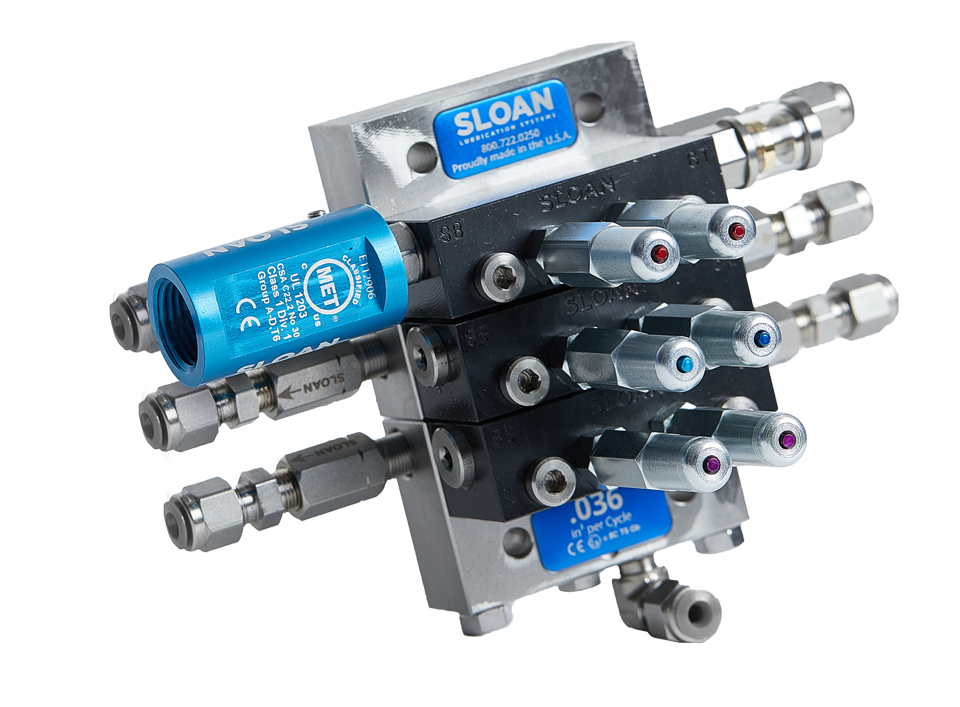

We arrived at the compressor station at the early hour of 7:30am and found our team already on the job and making great progress. As we looked at the work performed, we noted the artistry of the tubing installation featuring our exclusive SpaceClip™ tubing installation system, as well as the custom mounting and placement of our TriCip system. It was obvious that every aspect of this in-process installation was top notch and that our team takes a great deal of pride in their work.

We also had a video crew join us on site to record the team in action and capture their skills on camera.

When we had the chance to pull a few team members from their work for a quick interview, they walked us through the job and described how every aspect of the installation had been carefully considered, including the ease of ongoing maintenance, which is an indicator of future reliability. Our team members described where key components were located so that they would be protected from damage and environmental contamination, and how the systems, combined with the regular preventative maintenance covered by our Sloan Service Plans, will provide our customer reliability and peace of mind for years to come. Whatever your need, Sloan’s Service Team is here to help.

Did You Know?

Not all applications require the same lube rate. Gas composition, wear materials, pressure, and the presence of contaminants all contribute to the rates required for optimum performance. To find out more, reach out and talk with our Sloan Lubrication Systems experts.