A REDESIGNED OIL RECOVERY SYSTEM AND AN ATTENTION TO SYSTEM-WIDE DETAILS, SLOAN TARGETS OVER-LUBRICATION IN GAS COMPRESSION

Sloan Lubrication Systems (Sloan) has made it a mission to solve the pervasive problem of over-lubrication in the gas compression industry. Its TriCip system, which enables up to a 90% reduction in lubricant consumption using an automated control system and a proprietary lubricant, builds on decades of success Sloan has had with its Watchman lubrication system. The Watchman enables up to a 50% lubricant reduction by optimizing the flow rates to each delivery point and providing fail-safe monitoring. Rounding out Sloan’s lube reduction offerings is its recently redesigned oil recovery system (ORS).

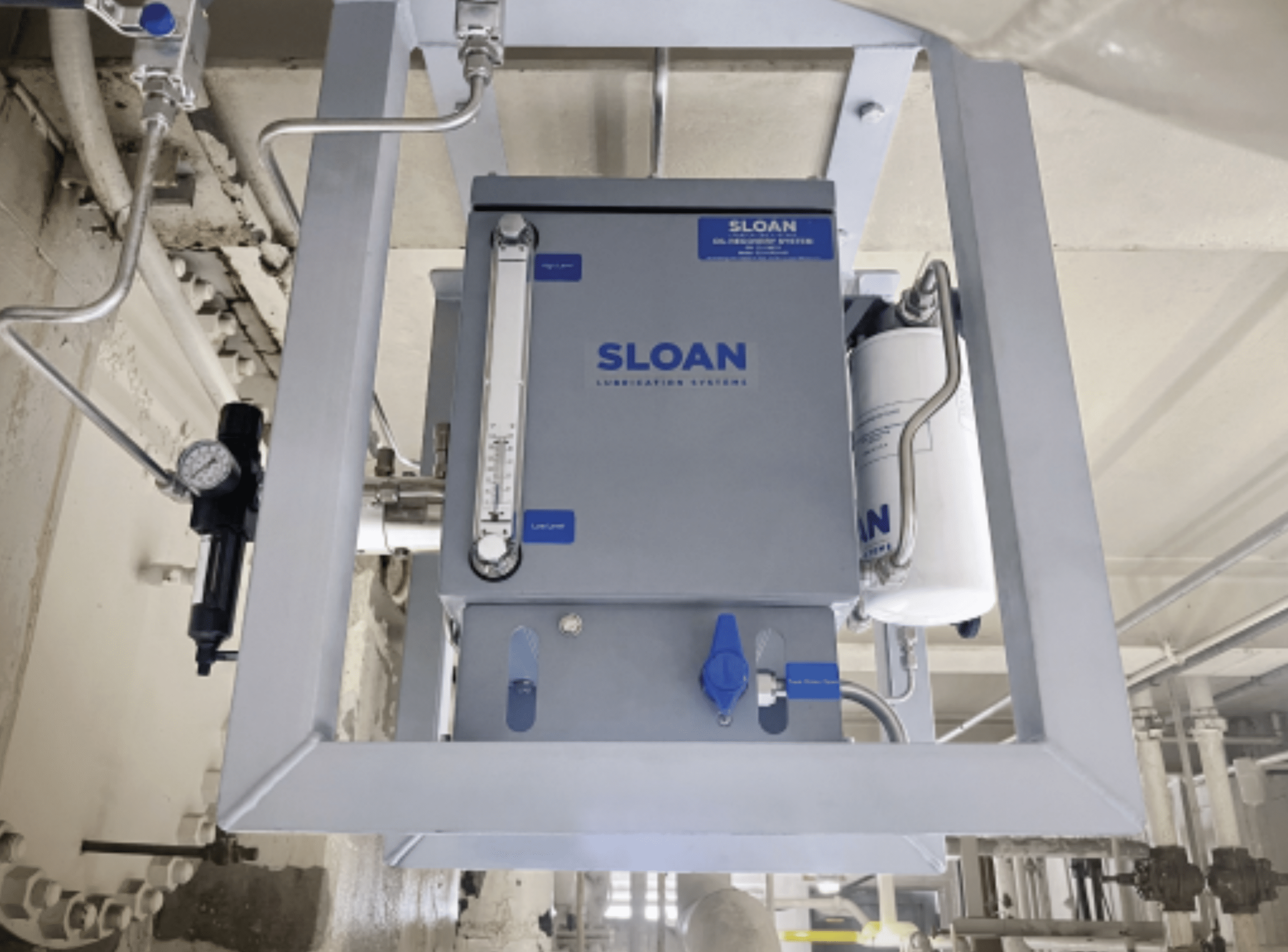

ORS is designed to prevent compressor crankcase oil waste. In most slow-speed gas compressor engines, some of the crankcase oil makes it past the wipers and into the distance piece. Excess oil flowing through the rod packing may also contribute significantly to oil waste. This oil is normally piped into a waste oil tank and disposed of. The ORS collects and filters the oil and returns it to the crankcase.

“The original ORS system was designed for doghouse recovery for an old slow-speed compressor,” said Matt McCarthy, senior sales representative at Sloan. The operating conditions were not particularly challenging. The redesign was to make the system more robust, reliable, and capable of meeting the requirements for a high-speed unit like an Ariel.”

gascompressionmagazine.com | MARCH 2023

According to McCarthy, ORS has been redesigned from scratch. “It has a new powder-coated tank designed specifically for the application with large access and cleans out. It has a higher-quality pump, a new water-absorbing filter, a level switch, and all stainless components. More importantly, the redesign increased the ORS operating pressure to 300 psi [20.6 bar].”

The daily amount of oil collected per compressor is typically between 2 and 4 gallons (8.8 and 17.6 L). The extent of the impact becomes apparent when considered over an entire pipeline footprint.

“If a compressor operator has 500 units that are all leaking an average of 3 gallons [13.2 L] per day, the cost of that wasted oil is equivalent to US$3,613,500 per year at US$11 per gallon, assuming a utilization rate of 60%,” said McCarthy. “ORS is a cost-effective, off-the-shelf solution that pays for itself quickly. It’s hard to imagine this type of expense being absorbed without question, but the cost of excess lubricant consumption can be hard to account for because it is spread over many locations. It is easy to overlook a few gallons per day at a single facility without thinking about the system-wide implications. Compressor operators are becoming aware of this, and there are currently several ORS pilot projects underway with great success.”

This system-wide approach is commonplace at Sloan. The company presented a paper titled “The High Cost of Over Lubrication” at the 2022 Gas Machinery Conference. The paper introduced an expense model for pipeline operators to calculate the hidden cost of over-lubrication from purchase to removal, and the costs of its negative impacts including valve failures, filter and metering station fouling, and gas stream contamination. The paper demonstrated how pipeline operators could boost the return on investment of future projects by utilizing lube reduction.

“Many compressor operators seem to think that if a little oil is good, then a lot of oil must be better. That is a mistake, and an expensive one at that,” said CJ Sloan, chief technology officer at Sloan and co-author of the paper. “In projects where we reduced lube rates anywhere from 50% to 90%, we have never had a compressor failure. In fact, it is quite the opposite. Compressors operate better when they get the right amount of lubricant and no more.”

One thing to consider before taking on lube reduction projects is proper design and system integrity. In most cases, operators cannot just reduce lube rates by 50% without causing problems. Most systems would not deliver the proper ratios of lubricant to both compressor and packing and need to be modified ahead of time. Lube reduction also decreases the margin of error, making the importance of regular preventative maintenance paramount.

“We’ve determined that the best way to guarantee success with lube reduction is to offer maintenance contracts, eliminating the burden of yearly testing and maintenance for operators,” said CJ Sloan. “This service has several advantages, including peace of mind and a reduced need for lube system training. In addition, if purchased with a new system, Sloan’s maintenance contracts can extend the warranty up to five years.

“Another key benefit is an immediate and impactful reduction to the carbon footprint of compressor operations,” added CJ Sloan. “Refining lubricant is extremely energy-intensive, and the feedstock itself is oil. Each gallon of lubricant saved has a carbon footprint of up to 29 lb. [13.2 kg]. At a time when pipeline operators are doing whatever they can to reduce their impacts, any effort that has a positive effect on both the environment and the bottom line is a no-brainer. And lube reduction does both.”

ABOUT THE AUTHOR

Eric Sloan is the marking communications manager at Sloan Lubrication Systems.

Eric joined Sloan Lubrication Systems in 2008 as a honing machine operator and held positions in assembly, operations, and served as an outside sales representative before assuming the duties of our Marketing Communications Manager in 2020. Eric earned his undergraduate degree from the University of Oregon and his MBA from the University of Portland in 2021.